Enterprise Communications

Our electronics manufacturing experts have supported all phases of product development and production for communications, and wireless OEMs and component suppliers.

Cellular & Satellites

Servers & Routers

Radio Frequency (RF)

Microwave Devices

Fiber Optic Devices

Transponders & Transceivers

Networked Audio & Video

Emerald's Customer Success Teams are there for you

Emerald’s dedicated Customer Success Teams will work with you at every stage of your product’s lifecycle, from concept to end-of-life, maximizing value and reducing time-to-market while ensuring you have the flexibility and logistical support to respond nimbly and quickly in this rapidly evolving market.

EMS for Communications & Wireless OEMs

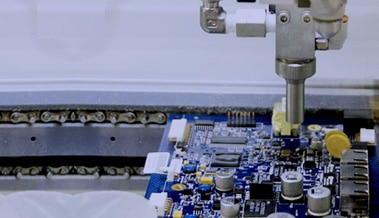

Emerald’s engineering and production experts bring decades of cumulative experience in developing and manufacturing general and custom printed circuit boards and system assemblies for cellular communication, satellites, servers and routers, radio frequency (RF) & microwave devices, fiber optic devices, transponders & transceivers and networked audio & video end-products.

Applications

- Flexible Manufacturing & Adaptable Supply Chain

- Swift & Scalable Production For Time-To-Market

- Reliability For Highly Configurable Parts

EMS FOR TELECOM APPLICATIONS

Operating with Design for Excellence (DFx) guidelines, lean manufacturing technology and methods, all Emerald facilities are fully certified and compliant with all manufacturing standards required by high-reliability telecommunications end-markets.

To ensure your project moves smoothly from design assistance to prototyping, assembly and testing, Emerald employs a customized and integrated program management system featuring robust data analysis, real-time transparent communications and rapid reconfiguration and retooling.

Seasoned Systems Engineers

Time-to-market is critical to success in the rapidly evolving telecommunications sector, no matter how innovative or transformative your product.

At Emerald, we specialize in engineering efficient, streamlined manufacturing programs that will expedite the development and roll-out of your new product while yielding the maximum return on your investment. Our New Product Introduction facility in Salem, New Hampshire, features consigned and turnkey Rapid Prototyping services, with turnarounds from one to five days, and a comprehensive suite of in-circuit and optical scan tests in compliance with rigorous regulatory and quality control standards for the communications industry.

Emerald’s seasoned systems engineers will work with you to design the optimal manufacturing process for your product, defining optimal workflow, then scale up and automate the process to eliminate bottlenecks and downtimes.

DFM, DFA & DFT

As Emerald’s partner-customer, you will work with a dedicated Customer Success Team, using Design for Manufacturability (DFM), Design for Assembly (DFA) and Design for Test (DFT) guidelines, technology and techniques.

Applications

EMS FOR TELECOM APPLICATIONS

Operating with Design for Excellence (DFx) guidelines, lean manufacturing technology and methods, all Emerald facilities are fully certified and compliant with all manufacturing standards required by high-reliability telecommunications end-markets.

To ensure your project moves smoothly from design assistance to prototyping, assembly and test, Emerald employs a customized and integrated program management system featuring robust data analysis, real-time transparent communications and rapid reconfiguration and retooling.

Seasoned Systems Engineers

Time-to-market is critical to success in the rapidly evolving telecommunications, no matter how innovative or transformative your product.

At Emerald, we specialize in engineering efficient, streamlined manufacturing programs that will expedite the development and roll-out of your new product while yielding the maximum return on your investment. Our New Product Introduction facility in Salem, New Hampshire, features consigned and turnkey Rapid Prototyping services, with turnarounds from one to five days, and a comprehensive suite of in-circuit and optical scan tests in compliance with rigorous regulatory and quality control standards for the communications industry.

Emerald’s seasoned systems engineers will work with you to design the optimal manufacturing process for your product, defining optimal workflow, then scale up and automate the process to eliminate bottlenecks and downtimes.

DFM, DFA & DFT

As Emerald’s partner-customer, you will work with a dedicated Customer Success Team, using Design for Manufacturability (DFM), Design for Assembly (DFA) and Design for Test (DFT) guidelines, technology and techniques.