Emerald Technologies was featured on:

KDRV-TV (ABC) NewsWatch 12 | “Made in Medford”

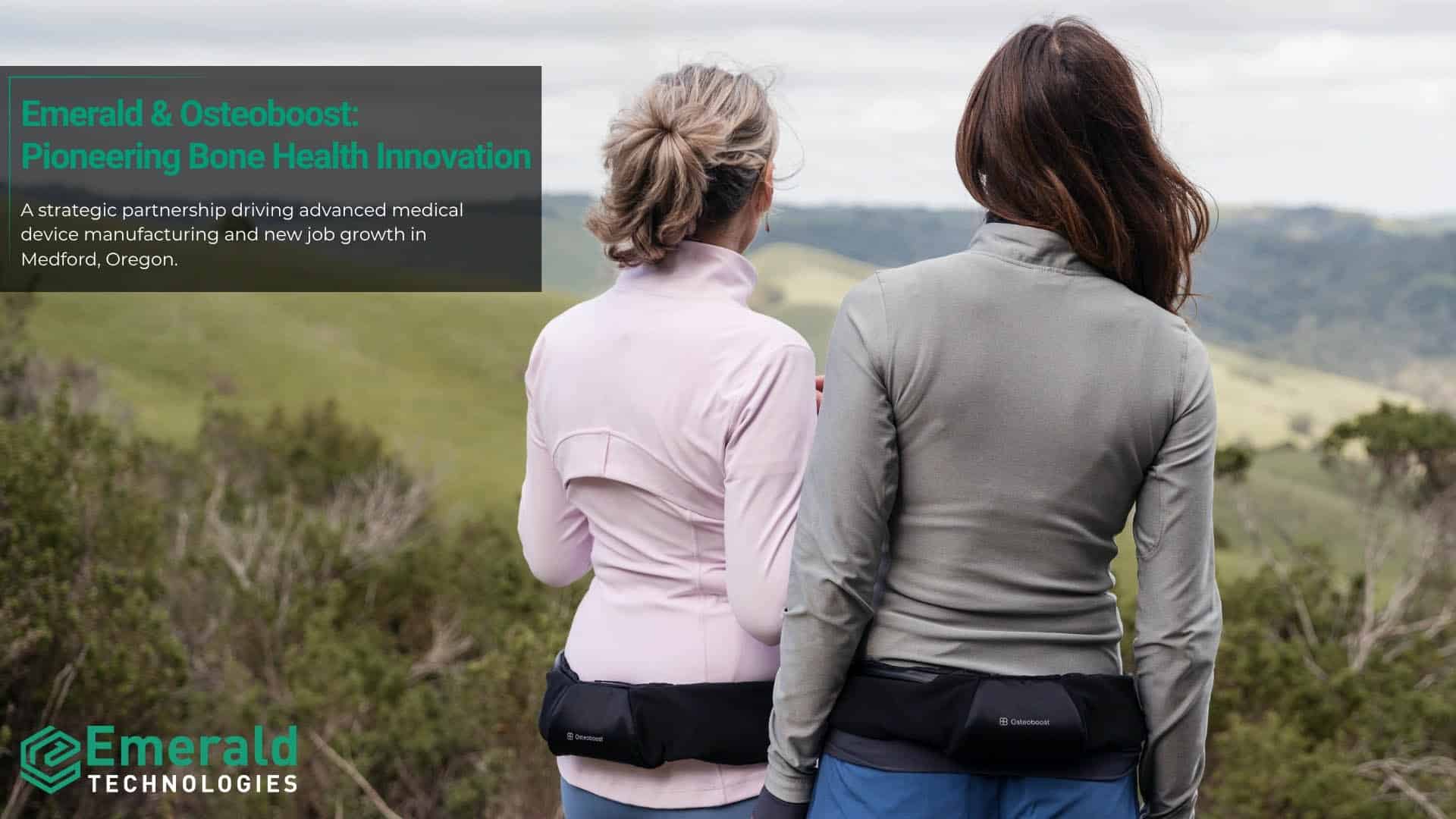

A New Era in Bone Health!

Osteoboost developed the first FDA-cleared wearable medical device clinically proven to help combat osteoporosis and reduce bone loss in the spine. Now, Emerald is honored to manufacture this groundbreaking device in one of our facilities in Medford, OR, by combining precision engineering, local expertise, and scalable production capabilities.

KDRV-TV

“Made in Medford”

In the segment, Amanda Brewer, President of Medford Emerald Technologies, shared how our team is hiring, training, and empowering local workers, proving that technology and community-driven manufacturing can deliver world-class results.

Emerald's Commitment to Medical Device Innovation

At Emerald, we partner with medical device innovators like Osteoboost to transform concepts into market-ready, high-quality products. From prototype and rapid scaling to regulatory support and production optimization, we deliver end-to-end manufacturing solutions that accelerate time-to-market with precision and confidence.

Our experienced engineering teams provide full lifecycle support – from embedded design, prototyping, and assembly to testing, distribution, supply chain management, and onshoring – all supported by a dedicated Customer Success Team.

Our Expertise Includes:

- Diagnostic Devices

- Therapeutic Devices

- Surgical Devices

- Patient Support & Assistive Devices

- Wearable & Home Healthcare Devices

- Laboratory & Research Devices

Need a medical device manufacturing partner?

Emerald Technologies is equipped to meet the demands and challenges of the constantly evolving advanced medical technology sector.

Capabilities:

Turnkey Box Build Solutions

We offer end-to-end assembly of fully integrated electronic devices – from PCBA and cable harnessing to enclosure fabrication and final system integration – with rigorous quality control and functional testing for high-reliability products ready for deployment.

Scalable Solutions & Expert Support

Whether prototyping, producing low-volume specialized builds, or scaling to full production, Emerald offers flexible solutions across multiple locations. Our engineering expertise, thorough testing, and dedicated support help bring high-performance, life-saving technologies to market efficiently.

Medical PCBA Manufacturing:

High Reliability & High Quality Electronics

As a trusted partner for the medical, biomedical, and safety industries, Emerald holds all required certifications for high-reliability PCBAs. Our facilities combine stringent process controls, advanced inspection technologies, and ISO 13485 certification to deliver PCBAs that meet the highest standards for safety, compliance, and reliability. From surgical devices to wearable healthcare systems, our PCBAs support life-saving innovation.

Medical-Grade Quality and Compliance

Our ISO 13485:2016-certified U.S. facilities meet the highest standards, including:

C Class 3 requirements

RoHS compliance

FDA registration

Current Good Manufacturing Practices (cGMP)

We also specialize in Tin-Lead to RoHS-compliant assembly and use a cutting-edge Track, Trace, and Control (TTC) system for full component-level traceability. Our Class 10K (ISO Class 7) cleanroom ensures superior contamination control for sensitive medical electronics.

Expertise • Flexibility • Commitment

Whether you’re launching your first medical device or scaling global production, Emerald has the expertise, flexibility, and local commitment to make it happen.

Read more about the KDRV NewsWatch 12 HERE or click link below: