Should we be passionate about this? YES…Why?

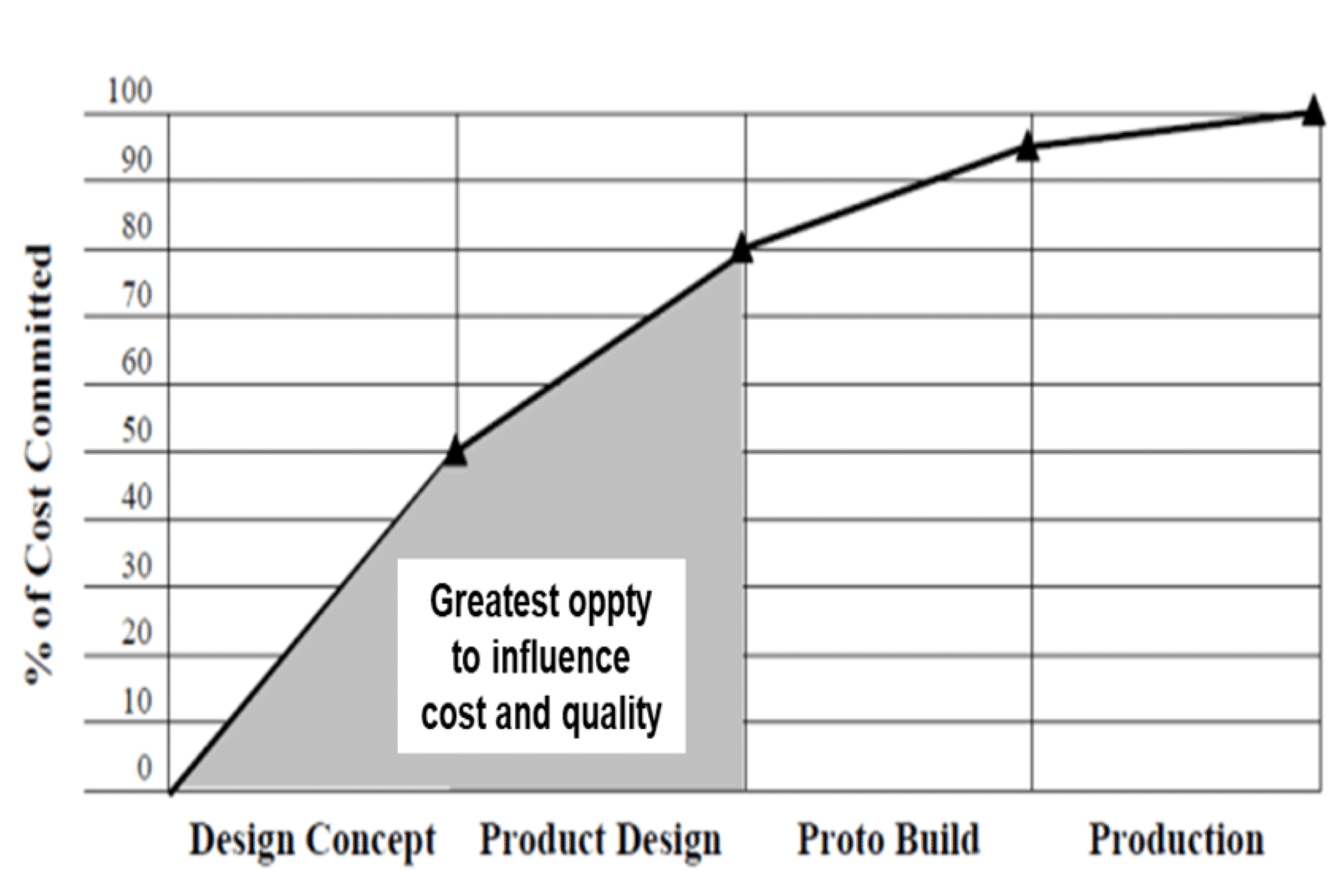

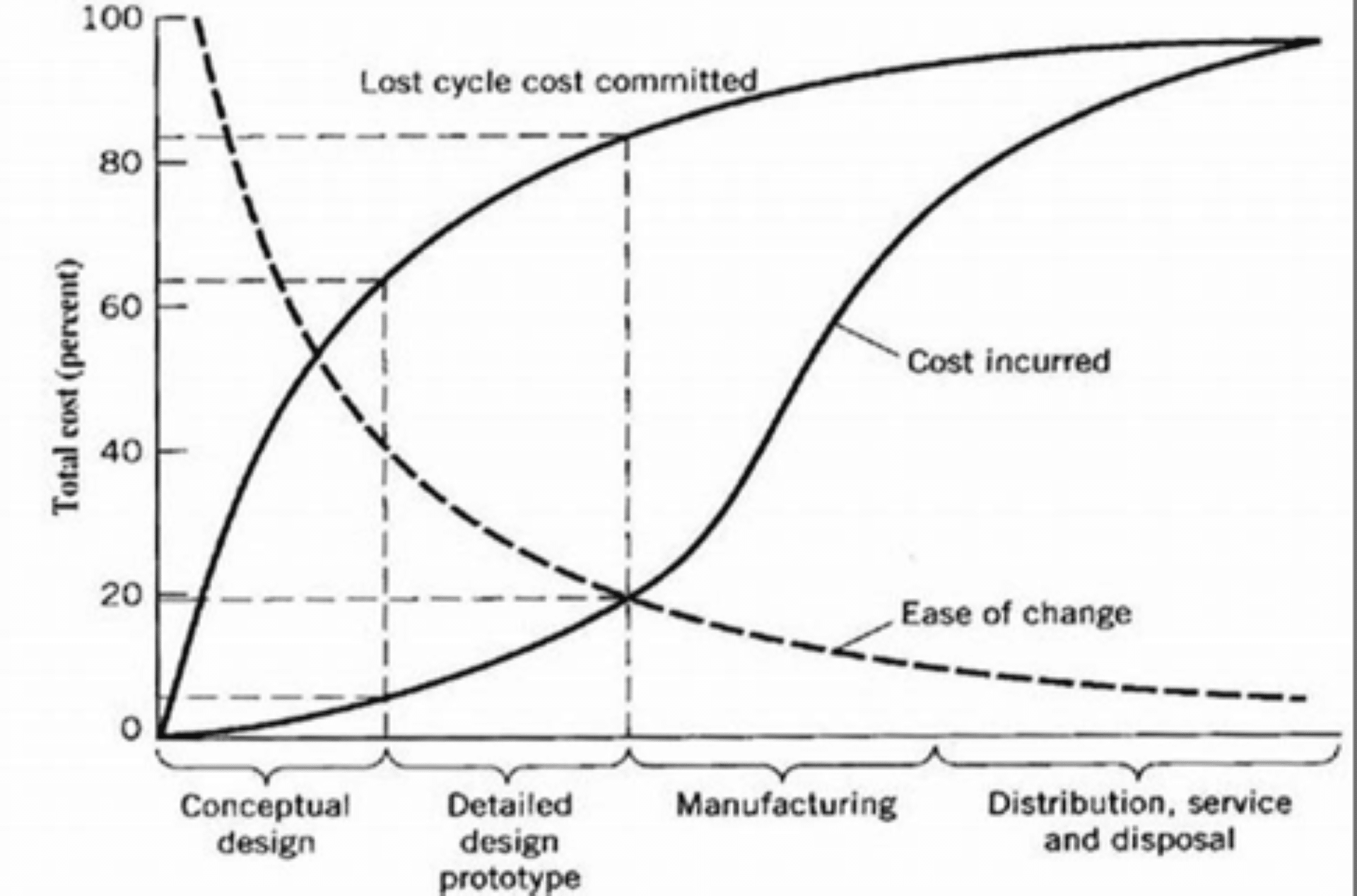

Because 75–80% of a new product’s cost and “designed‑in quality” is determined and semi-anchored before the prototype build even begins.

That means your greatest opportunity to influence reliability, manufacturability, cost, and speed-to-market happens early, very early.

DFM is not an optional step. It’s the foundation for a stable product lifecycle.

DFMs Are Based On:

Industry Standards

- IPC‑2221 – Generic standard for PCB design

- IPC‑7095 – Design and assembly for BGAs

- IPC‑7525 – Stencil design guidelines

- IPC‑SM‑7531 – Surface-mount design practices

Advanced Tooling

- Valor DFM analysis

DFM Process on PCBA: Our 3-Step Process

STEP 1: Fab Review (Pre-Route)

Focus – Major component placement

- Identify high-impact issues early

- Review component clearances, orientations, and process-critical features

- Discuss initial findings with the customer

STEP 2: Fab Review (Post-Route)

Focus – Full component placement

- Deep-dive analysis on final placement and routing

- Evaluate manufacturing risk areas using Valor and internal expertise

- Review concerns and recommendations with the customer

Addressing potential issues before the board is released to fabrication saves time and costs and prevents avoidable quality problems.

STEP 3: Product Build & Ongoing DFM

Once the board enters production:

- Extensive process and product quality data is collected

- Internal quality teams assess DFM vs. non-DFM issues

- Findings are shared with customers in ongoing reviews to continuously improve future builds

Examples of Feedback by Category

Here are common categories where DFM catches issues before they become build problems:

BOM vs Layout

- Items in BOM but missing in ECAD

- Package mismatches (e.g., 0603 vs 0402)

Footprint Library

- AML ↔ footprint mismatches

- Multiple AMLs with different footprints

- Footprint changes based on experience

- Footprint doesn’t match datasheet

Placement Issues

- Clearance to TH pins, BGA, edges

- Physical interference between components

- Improper height clearances

Fabrication Issues

- Missing fiducials

- Open via‑in‑pad

- Silk art on pads or vias

- Unbalanced trace widths (< 3:1)

Process Issues

- SMT vs. TH vs. press-fit considerations

- Poor panelization strategies

- Inadequate thermal relief for TH parts

What Happens When Issues Are Not Fixed? (Real Examples)

EXAMPLE 1: Insufficient Solder + Poor Alignment

Issue: Component appears to have insufficient solder, and alignment is poor

Findings, Recommendations, and Actions:

- Root cause – bad footprint in CAD

- Customer to fix ECAD library and refresh symbol on the next spin

- Apply correction to all future new boards to prevent repeat issues

EXAMPLE 2: Solder Bridging Between Adjacent Through-Hole Components

Issue: Solder bridging between two adjacent through-hole components

Findings, Recommendations, and Actions:

- The footprint itself was OK, but the component-to-component spacing was too close

- Move the component on future layouts to increasing spacing

- Customer to add a small keep-out area to the ECAD library to accommodate the solder-wave process and prevent bridging

Quality Data and Analysis: A Passion

We base every recommendation on data, not guesswork.

Our Analysis includes:

- High-level summaries and Pareto charts

- Breakdown by process step

- By job number

- By assembly number

- Trend analysis over time

Quality data drives better decisions, smoother builds, and continuous improvement.

It Really Makes a Difference!

We’ve seen firsthand how DFM involvement transforms outcomes, including an actual letter from a customer engineer thanking the team after DFM-guided changes dramatically improved their yield and reduced rework.